Mechanical Engineering

With all production stages carried out under one roof. From part manufacturing to assembly and final testing. We are able to manage the entire production process from drawings to final products. This integrated approach ensures consistent quality, full control and a cost efficent production.

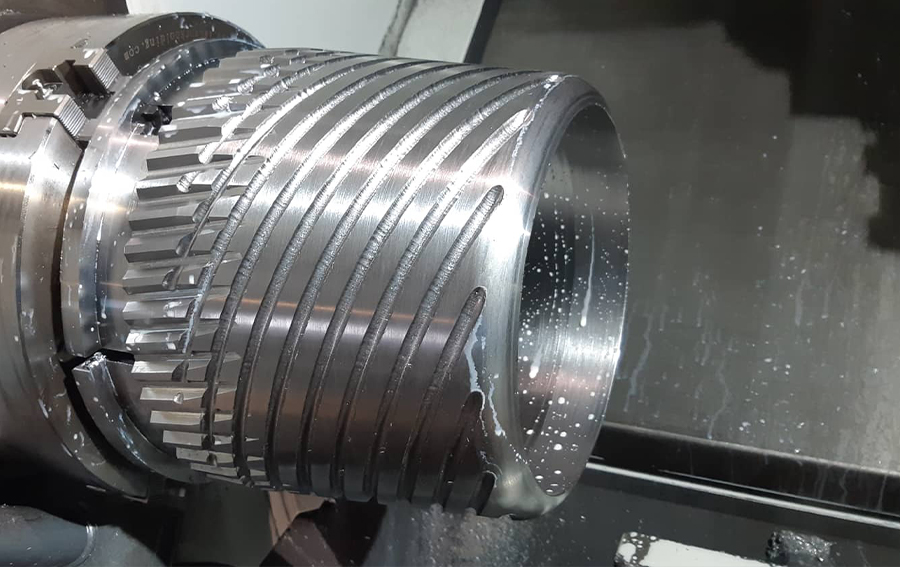

Mechanical Processing

We perform mechanical production using modern, high-precision machinery. Our capabilities include CNC machining, tube and plate laser cutting, bending, and other machineries. With a strong focus on accuracy, quality, and full technical compliance, we deliver reliable results that meet demanding industrial standards.

Assembly

Our assembly services are designed for industrial clients who require reliable, high-quality solutions and optimize their production processes. Building on H-Metal’s decades of experience in metalworking and our ISO 9001:2015 certification, we provide flexible, professional assembly work that meets even the most demanding technical requirements.

We install and integrate components for industrial systems:

Pneumatics – installation of compressed-air mechanisms and control systems

Hydraulics – integration of fluid-powered devices and transmission systems

Electrical systems – wiring, sensors, motors, and control panels

Mechatronics – combining mechanical and electronic components for automation solutions

Welding Skills

H-Metal provides extensive welding services, combining years of experience with high technical expertise and aproducts that requires the highst welding certifications. Our certified welders ensure precision and compliance with international standards.

Materials we work with: ● Steel ● Stainless Steel

Welding processes ● TIG welding (Tungsten Inert Gas) ● MIG/MAG welding (Metal Inert/Active Gas) ● Welding current up to 630A

Our strengths: ● Decades of experience in metalworking ● Certified and highly skilled welders ● Quality guaranteed under ISO 9001:2015 certification ● Welders certified according to EN ISO 9606-1 and PED 2014/68/EC

Design & Engineering

H-Metal offers comprehensive design and engineering solutions, supporting product development from initial concept to detailed technical drawings.

Our Team: ● Engineers and technicians with high educational backgrounds ● Extensive experience in mechanics and machine building

Software competence: We use all major 3D CAD programs, including: ● SolidWorks ● AutoCAD ● Inventor ● Fusion 360

Services ● Preparation of technical drawings for various projects and equipment ● Development of prototypes and custom solutions ● Optimization of structures for production and assembly ● Ensuring feasibility, quality, and smooth collaboration with production

Surface Treatment & Painting

We provide complete surface treatment and painting solutions, from preparation to final finishing. Our processes ensure maximum corrosion protection, long-term durability, and visually appealing results.

Surface Preparation ● Sandblasting and wet cleaning to remove corrosion and old coatings ● Chemical cleaning and degreasing to improve paint adhesion

Coating processes ● Wet painting with acrylic-based paints for complex surfaces

Final Finishing & Quality Control ● Coating thickness measurement ● Visual inspection and documented compliance before delivery

Technical Capabilities ● Painting chamber size: 13 × 8 m